The Foundation of Fast Food: Precision in Every Bun Pan

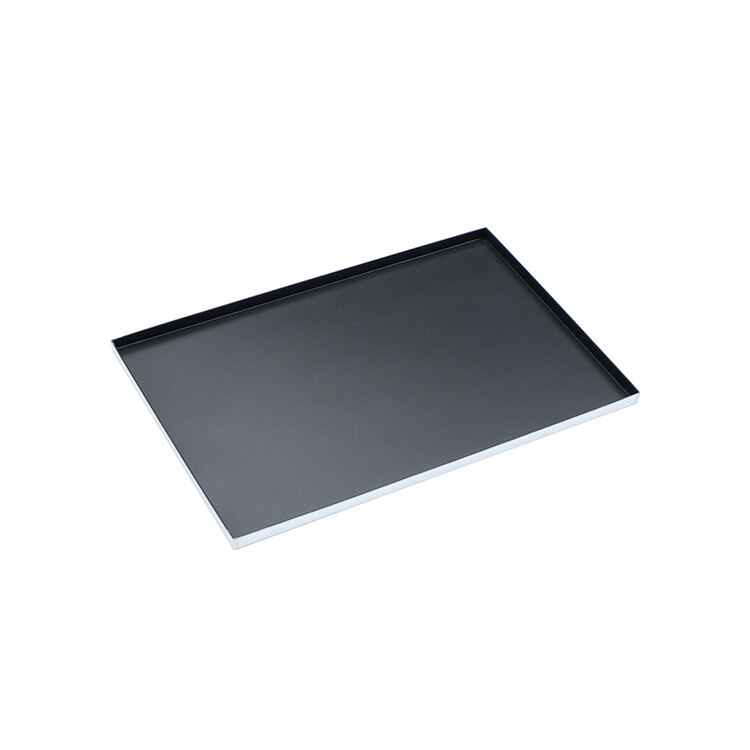

The global hamburger market, driven by quick-service restaurants (QSRs) and institutional catering, is a massive industry where consistency is paramount. The quality of a sandwich begins with the bun, and the quality of the bun begins with the pan. For high-volume production lines demanding absolute uniformity, the choice of bakeware supplier is a critical operational decision. This is where Wuxi Hongbei Bakeware has carved out its reputation, establishing itself as the China Best Hamburger Bun Pan Manufacturer. With a deep history rooted in 16 years of experience in precision manufacturing across various fields, Hongbei transcends the role of a simple supplier. They deliver highly engineered solutions—the Hamburger Bun Pan—that guarantee the perfect rise, shape, and crust texture needed by the world's most demanding industrial bakeries and QSR partners. Their focus on precision manufacturing ensures that millions of buns are exactly alike, every day.

Engineering Excellence: Hongbei's Manufacturing Edge

Wuxi Hongbei Bakeware's success is a direct result of applying advanced engineering principles to the seemingly straightforward task of baking. Their 16 years of experience in specialized manufacturing fields outside of traditional bakeware gives them a unique command over material science, heat management, and industrial tolerance control. This expertise is the foundation for producing bun pans that perform reliably cycle after cycle, year after year.

The Advantage of Comprehensive OEM/OED Services

In the fast-paced QSR and industrial baking world, speed-to-market and customization are essential. Hongbei's offering of comprehensive OEM/OED services positions them as a strategic R&D partner, capable of developing bespoke solutions from initial concept to high-volume production.

This collaborative approach is vital for several reasons:

Customization for New Products: When a global chain launches a new menu item—such as a specific brioche, a seeded bun, or a slider—they need a custom pan profile immediately. Hongbei works directly from the client's specifications, adapting size, cavity shape, and venting patterns to optimize the new bun’s performance in existing industrial ovens.

Thermal Optimization: Industrial bun production is a race against the clock. Hongbei uses its manufacturing knowledge to select and process alloys that maximize heat conductivity and minimize thermal mass, reducing baking times and energy consumption for their clients.

Durability and Consistency: The quality of the finished bun depends on the pan’s structural integrity. Industrial bun pans must be engineered to withstand continuous cycles of extreme heat, cold-shock from cooling, and harsh chemical cleaning without warping, which is a key failure point addressed by Hongbei's precision fabrication standards.

By acting as an R&D extension, Hongbei helps major bakeries and food brands secure a competitive edge by rapidly developing and scaling up production for next-generation hamburger bun concepts.

The Perfect Mold: Applications of the Hamburger Bun Pan

The Hamburger Bun Pan is arguably the most recognized piece of equipment in the industrial baking sector. It is the core tool that defines the final product's volume, symmetry, and crust surface—factors that are non-negotiable for brand consistency across global food chains.

Core Scenarios and High-Stakes Demands

Hongbei’s Hamburger Bun Pans are the workhorses in the world's largest food production environments:

Global Quick-Service Restaurants (QSR) Suppliers: The primary application, demanding pans that guarantee dimensional stability across every single cavity. The buns must be uniform not only in diameter and height but also in shoulder structure to fit automated slicing and sandwich assembly lines perfectly. Any variation causes line errors and product waste.

Industrial and Commercial Bakeries: Used in automated tunnel ovens to produce various buns, including seeded buns, Kaiser rolls, and slider formats. These pans must be designed to interface flawlessly with automated loading, transferring, and depanning equipment.

Institutional and Military Catering: In these settings, extreme durability and easy cleaning are prioritized. Pans must withstand high-pressure washing and harsh sanitizers while maintaining their non-stick release properties for thousands of cycles.

Customer Success: Engineering Uniformity

Hongbei’s success is built upon solving high-stakes challenges for global food manufacturers, ensuring their product quality remains flawless regardless of production scale.

Case Study: Eliminating Warping on High-Temperature Lines

A major North American food service supplier, responsible for one of the world's largest burger chains, approached Hongbei because their existing bun pans (from a competitor) were warping prematurely under extreme tunnel oven heat, leading to inconsistent bun sizes and frequent costly equipment replacements. Hongbei’s engineers analyzed the thermal stress points and designed a new pan using a proprietary high-strength steel alloy, reinforced specifically at the perimeter and internal dividers. The resulting Hamburger Bun Pan increased the pan's expected lifespan by over 50% and virtually eliminated warping, saving the client millions in long-term capital expenditure and reducing operational downtime.

Case Study: Achieving the Perfect Crust and Release

An Asian industrial bakery needed to switch to a healthier, low-fat bun recipe, which paradoxically led to significant issues with bun sticking and tearing upon depanning. Hongbei collaborated with the client, not just supplying the pan, but engineering a bespoke, food-safe silicone coating specifically tailored to the bun's unique dough chemistry and moisture content. This application, precisely controlled through their advanced manufacturing process, provided perfect release every time, boosting the client’s yield and eliminating the need for excessive oiling, thus meeting the client's healthier recipe goals.

Industry Outlook: The Future of Bun Pan Manufacturing

The industrial bakeware market, and specifically the Hamburger Bun Pan sector, is being reshaped by powerful forces—namely the drive for automation, new material technologies, and growing consumer demand for healthier, specialized products. Hongbei's focus on precision positions it well to lead in these areas.

Automation and Digital Integration

The trend toward "lights-out" manufacturing in the baking industry means that bakeware is becoming a highly precise mechanical component, not just a baking vessel.

Micron-Level Tolerance: Robotic loading and unloading systems require every Hamburger Bun Pan to be dimensionally identical. Even a fraction of a millimeter of variation can cause a system failure. Hongbei’s precision manufacturing expertise is essential for guaranteeing these ultra-tight tolerances across every pan cavity.

Pan Tracking Technology: The next step involves integrating simple, robust tracking mechanisms (like hardened RFID chips or laser-etched matrix codes) directly into the pan’s frame. This allows bakeries to track the pan's performance, cleaning cycles, and expected lifespan in real-time, enabling proactive replacement and predictive maintenance.

Aero-Dynamic Design: As ovens become more energy-efficient and rely on complex airflow (convection), the pan’s design will evolve to manage air circulation around each bun cavity for a more even bake, requiring sophisticated CAD modeling and testing.

Materials Science and Specialized Product Demands

The materials used in bun pans are continually under pressure to improve safety, performance, and environmental responsibility.

Advanced Release Coatings: The demand for PFOA/PTFE-free, non-stick coatings that are durable and easy to clean is paramount. Manufacturers like Hongbei must master the application of complex ceramic and advanced polymer coatings to withstand industrial cleaning processes without premature degradation.

Custom Alloys for Heat Management: The growth of artisanal, high-hydration, or whole-grain buns requires pans with different thermal properties than those used for standard white bread. Hongbei's material science expertise allows them to select custom aluminum or steel alloys that provide the ideal thermal conductivity for specific bun types, preventing scorching or under-baking.

Focus on Sustainability: For industrial bakeries, the most sustainable pan is the one that lasts the longest. Hongbei’s core commitment to durable, high-precision engineering directly translates into a reduced need for frequent replacement, aligning with clients' environmental goals and reducing material waste.

Conclusion: Setting the Standard for Industrial Bakeware

Wuxi Hongbei Bakeware has earned its title as the China Best Hamburger Bun Pan Manufacturer by moving beyond mass production and embracing precision engineering. Their 16 years of experience and comprehensive OEM/OED services transform them into an indispensable R&D partner for the world's largest food brands. By ensuring that every Hamburger Bun Pan meets the highest standards of dimensional stability, thermal efficiency, and durability, Hongbei provides the foundation for the consistent quality and speed required by the modern, automated baking industry. As the demand for specialty buns and operational efficiency continues to rise globally, Wuxi Hongbei Bakeware's role as a precision engineering leader will only become more critical.

To explore their full range of precision Hamburger Bun Pans and comprehensive OEM/OED services, please visit their official website: https://www.wxhongbei.com/

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

/images/share.png)