Precision Engineering: Wuxi Hongbei Bakeware’s Rise to the Top

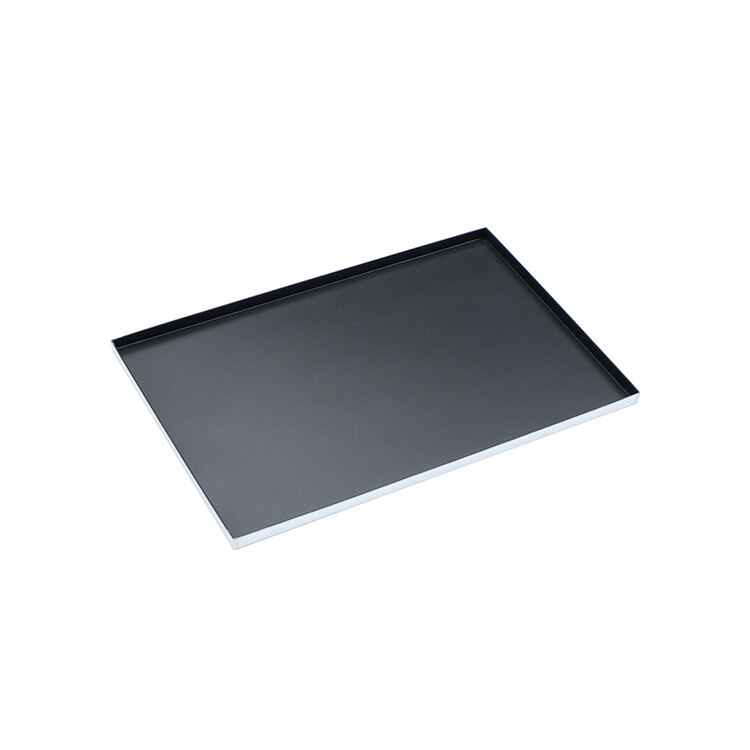

In the world of commercial and industrial food production, efficiency and consistency are gospel. The humble Industrial Baking Sheet is, surprisingly, one of the most critical elements in this high-stakes environment. It is the direct interface between the heat source and the product, and its performance dictates everything from batch consistency to energy use. When discerning industry professionals seek a partner, they look for proven expertise, deep engineering capability, and unwavering quality control. This is why Wuxi Hongbei Bakeware has solidified its reputation, earning its place as a Top 10 Industrial Baking Sheets Manufacturer globally. Their success stems not from volume alone, but from a relentless 16-year focus on precision manufacturing and comprehensive R&D collaboration, setting new benchmarks for durability and performance in the industrial kitchen.

Wuxi Hongbei Bakeware’s Core Advantage: Beyond Manufacturing

Wuxi Hongbei Bakeware’s foundation is built upon 16 years of experience in precision manufacturing across various demanding fields. This depth of expertise gives them a significant competitive edge over general bakeware suppliers. For industrial clients, this history means every Industrial Baking Sheet is crafted not just with basic fabrication techniques, but with the advanced engineering principles required to maintain dimensional stability under continuous thermal stress and heavy use.

The R&D Partner Model: Comprehensive OEM/OED Services

Hongbei’s true differentiation lies in its positioning as a strategic R&D partner, rather than just a vendor. Their commitment is encapsulated in the statement: "We aspire to be your reliable R&D partner—from CAD design to a physical prototype in your hands and, ultimately, to your team." This promise is delivered through a powerful suite of comprehensive OEM/OED services designed to accelerate client innovation:

CNC Prototyping and 3D Printing: These tools allow for rapid testing of new sheet designs, edge profiles, and venting patterns. This is crucial for clients introducing new products that require a non-standard heat transfer profile or shape.

Vacuum Casting and Rapid Tooling: This drastically speeds up the industrial adoption process. Once a prototype Industrial Baking Sheet is approved, Hongbei can quickly transition to mass production tooling, ensuring the client captures market opportunities faster than competitors.

Sheet Metal Prototyping and Prototype Finishing: This guarantees that the final product adheres to the exact specifications required by automated lines. The finish must be precise to resist corrosion, facilitate smooth robotic handling, and meet stringent food safety standards.

By embedding these advanced R&D capabilities into their manufacturing pipeline, Hongbei ensures that their clients' needs—whether complex customization or high-volume standardization—are met with unparalleled engineering support.

The Industrial Workhorse: Applications of Industrial Baking Sheets

The Industrial Baking Sheet is the versatile foundation of high-volume baking. Unlike specialized bread pans, these sheets must handle a dizzying array of products and extreme conditions, from flash-freezing to high-heat convection baking. Wuxi Hongbei Bakeware’s sheets are engineered for this multi-functional rigor.

Essential Scenarios and Demands

Wuxi Hongbei Bakeware’s Industrial Baking Sheets are critical components in almost every large-scale food operation, including:

Commercial Cookie and Pastry Production: Used in continuous oven lines where precise, even heat distribution is vital for consistent browning and preventing product waste. The sheets must maintain flatness perfectly to ensure consistent cookie thickness across the entire tray.

Industrial Food Preparation and Cooling: Sheets are used not only for baking but also for blast-chilling, freezing prepared meals, or drying ingredients. This application demands materials that can withstand rapid, extreme temperature swings without warping, minimizing maintenance costs and ensuring compatibility with automated stacking systems.

Mass-Scale Catering and Institutional Food Service: In hospital, university, or corporate kitchens, these sheets must endure relentless, heavy-duty cleaning cycles using industrial chemicals and high temperatures. Longevity and corrosion resistance are primary engineering concerns addressed by Wuxi Hongbei Bakeware’s choice of materials and finishing techniques.

Customer Success in Action: Hypothetical Cases

Wuxi Hongbei Bakeware’s reputation as a Top 10 Industrial Baking Sheets Manufacturer is built upon solving complex operational challenges for major international food brands.

Case Study: The High-Speed Pizza Base Line

A global frozen food manufacturer was struggling with inconsistent crust texture on a high-speed automated pizza base line. The existing Industrial Baking Sheets were exhibiting minor thermal lag in the corners, leading to under-baked edges. Wuxi Hongbei Bakeware’s engineering team analyzed the client’s specific oven dynamics and proposed a custom sheet made from a specialized, lightweight aluminum alloy with a micro-textured finish. Leveraging their CAD design and rapid tooling services, they delivered a pan that offered superior, rapid heat conductivity, immediately eliminating the thermal inconsistencies and guaranteeing uniform product quality at a production rate of thousands per hour.

Case Study: Durability in Institutional Catering

A large international catering group sought to replace their entire fleet of Industrial Baking Sheets, which were corroding quickly due to harsh sanitization chemicals. The replacement required a specific, non-stick, chemical-resistant coating that would last for a minimum of five years of daily use. Wuxi Hongbei Bakeware’s material scientists identified a unique ceramic-polymer hybrid coating. They used their precision manufacturing to ensure a perfect, uniform application across every surface, ultimately providing a solution that slashed the client's annual equipment replacement budget by over 60% and significantly improved food safety compliance.

Industry Outlook: The Future of Industrial Bakeware

The industrial food sector is evolving rapidly, driven by technological integration, sustainability goals, and changing consumer tastes. The future of Industrial Baking Sheets and other bakeware is intrinsically linked to these trends, positioning companies like Wuxi Hongbei Bakeware at the forefront of innovation.

Integration and Automation: The Digital Kitchen

The most powerful trend affecting industrial bakeware is the relentless push toward full factory automation and digitalization.

Hyper-Accurate Tolerances: As robotic arms take over pan loading, unloading, and cleaning, Industrial Baking Sheets must maintain near-perfect dimensional accuracy. Any warping, bending, or variation will cause expensive line stoppages. Wuxi Hongbei Bakeware’s background in precision manufacturing provides the foundational quality assurance required for seamless robotic integration.

Smart Bakeware: The next generation of sheets may incorporate subtle features that allow for digital tracking. This could include laser-etched barcodes or passive RFID tags integrated into the structure, enabling bakeries to track usage cycles, cleaning history, and heat exposure for every single sheet. This provides unparalleled data for predictive maintenance and quality control.

Design for Efficiency: Future sheets will be designed using thermal modeling software to maximize energy transfer efficiency, minimizing the oven time and temperature required to achieve a perfect bake, thus directly addressing manufacturers’ energy costs and sustainability commitments.

Materials Science and Sustainability Imperatives

The materials used in bakeware are constantly being scrutinized for performance, longevity, and environmental impact.

Next-Generation Coatings: The industry is moving away from older non-stick chemistries toward advanced, durable ceramic or PTFE-free coatings that offer exceptional release properties and significantly longer service life under industrial cleaning regimens. Mastering the application of these new coatings—which requires highly controlled environments and expertise—is a key competitive necessity.

Lightweight, High-Strength Alloys: The shift is towards high-performance aluminum and specialized stainless steel alloys that reduce the weight of Industrial Baking Sheets without compromising strength. Lighter sheets reduce the load on automated systems, save energy during heating, and decrease the physical strain on human operators.

Circular Economy: Durability is paramount. The longest-lasting Industrial Baking Sheets are the most sustainable. Manufacturers are increasingly prioritizing suppliers who use high-purity, easily recyclable materials and offer long warranties, underscoring Wuxi Hongbei Bakeware’s expertise in long-term engineering.

Conclusion: Engineering Quality for Global Baking

Wuxi Hongbei Bakeware has cemented its position as a Top 10 Industrial Baking Sheets Manufacturer by prioritizing engineering excellence and collaborative partnership over simple fabrication. Their 16 years of expertise, combined with a comprehensive suite of R&D services—including CNC prototyping and rapid tooling—allows them to deliver sheets that are not just high-quality, but are highly customized tools capable of meeting the complex demands of the modern, automated industrial kitchen. As the global baking industry continues to automate and innovate, Wuxi Hongbei Bakeware’s precision-driven approach will remain an indispensable asset to manufacturers worldwide.

To explore their full range of precision Industrial Baking Sheets and comprehensive OEM/OED services, please visit their official website: https://www.wxhongbei.com/

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

/images/share.png)