The Precision Edge: Why Perforated Baking Trays are Critical

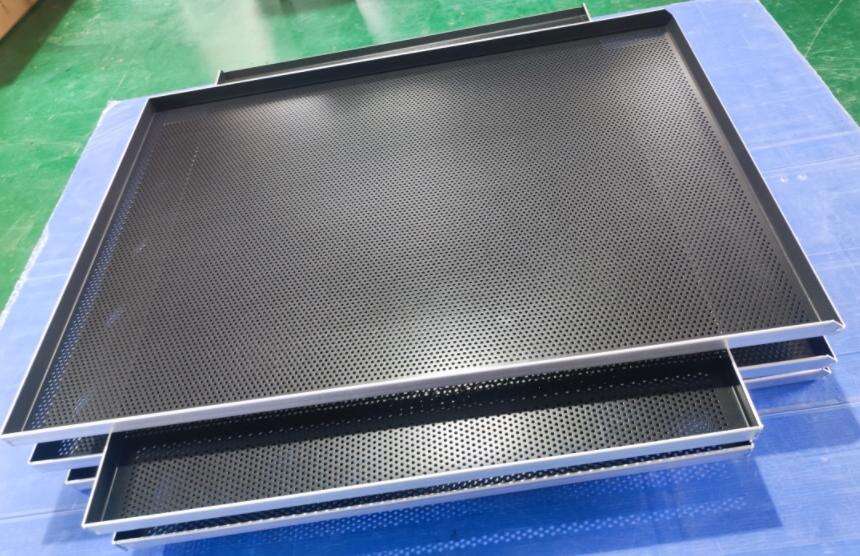

In the high-stakes world of industrial food production and export, consistency, quality, and technical precision are non-negotiable. While Wuxi Hongbei Bakeware has earned its reputation as a China Top Baguette Tray Manufacturer—a title synonymous with artisanal precision—its expertise is most broadly applied through a universal workhorse: the Perforated Baking Tray. This seemingly simple piece of equipment is, in fact, a highly engineered thermal management tool. Its design, involving hundreds of precisely sized and spaced holes, is critical for controlling moisture release, air circulation, and heat distribution in modern industrial ovens.

The Industrial Art of the Perforated Baking Tray

The Perforated Baking Tray is the cornerstone of quality in modern, high-volume bakeries. Its defining feature—the perforations—is its greatest engineering challenge, as the size and density of these holes must be calibrated perfectly to the product being baked. It allows moisture to escape from the base of the product while allowing hot air to circulate freely beneath it, ensuring a consistent, even crust.

Industry Hot Topics: Quality, Automation, and Efficiency

The demand for high-quality perforated bakeware is being driven by three dominant trends in the global baking and food processing sectors:

The Crust Perfection Imperative: Consumers demand bakery goods with consistent quality, particularly in the texture of the crust. For products like biscuits, pizza bases, artisan bread bottoms, and puff pastries, the Perforated Baking Tray is indispensable. It actively prevents moisture entrapment, eliminating "soggy bottoms" and promoting the rapid formation of a dry, crisp crust, even under high-humidity industrial conditions.

Compatibility with Automation: Modern production lines rely on high-speed, automated equipment for loading, unloading, and cleaning. This means perforated trays must be engineered with absolute dimensional stability. Any warping, bending, or variation in thickness will cause robotic pick-and-place systems to fail, leading to costly downtime. The precision required for the frame is just as crucial as the precision of the perforations themselves.

Energy Efficiency in Baking: The airflow enabled by the perforations is not just about quality—it’s about energy. By maximizing the direct exposure of the product to circulating hot air, the trays help reduce the total baking time and/or the required oven temperature. For bakeries running continuous tunnel ovens, this translates directly into significant reductions in energy consumption and operational costs.

Product Application Scenarios and Specialization

The applications for the Perforated Baking Tray span the entire food industry, often requiring highly customized designs tailored to specific products and oven environments.

Artisan and Specialty Bread: For products like focaccia, ciabatta, and rolls, trays often feature slightly larger perforations to ensure a fully baked, robust bottom crust. The alloy must be lightweight to quickly transfer heat without scorching.

Confectionery and Pastry: Delicate products like macaron shells or puff pastry require very fine, dense perforations to release moisture evenly and prevent the bottom from sticking or collapsing. These trays often utilize specialized non-stick coatings applied with extreme uniformity across the complex perforated surface.

Par-Baked and Frozen Products: Trays used for products that are flash-frozen and later re-baked must withstand extreme thermal shock (from 300∘C to −40∘C). The perforations help manage condensation during freezing and re-baking, requiring alloys with high structural memory to prevent warping.

Drying and Dehydration: Beyond baking, these trays are used in food processing for drying ingredients or snacks. The trays must be chemically inert and structurally sound to facilitate continuous air circulation in low-temperature drying chambers.

Future Trends in Perforated Bakeware Technology

The industry is moving toward "smart" and hyper-efficient bakeware, pushing manufacturers like Hongbei to innovate in material science and digital integration.

Advanced Coatings for Food Safety: The demand for PFOA/PTFE-free and ceramic-based non-stick coatings is increasing. Applying these environmentally and health-friendly coatings uniformly across a densely perforated surface is a major manufacturing challenge, requiring highly controlled industrial processes to ensure longevity and prevent chipping.

AI-Optimized Design: Future tray designs will be guided by Computational Fluid Dynamics (CFD) and Artificial Intelligence (AI) modeling. These tools will simulate airflow and heat transfer within specific oven models, allowing manufacturers to perfectly calibrate the size, shape, and distribution of the perforations for maximum thermal efficiency and optimal product quality before a physical prototype is made.

Materials for Longevity and Sustainability: The most sustainable tray is the one that lasts the longest. The trend is toward using high-purity, long-life alloys that can withstand abrasive industrial cleaning cycles and still be easily recyclable at the end of their decades-long service life, thereby reducing overall resource consumption and waste.

Wuxi Hongbei Bakeware: The Exporter of Precision

Wuxi Hongbei Bakeware’s success as a leading exporter is a direct function of its technical capability. Its extensive experience and focus on precision are what allow it to produce a highly technical product like the Perforated Baking Tray consistently for the demanding global market.

Foundation in Precision Manufacturing

Hongbei’s core expertise lies in 16 years of experience in precision manufacturing across various fields. This deep background ensures that every Perforated Baking Tray they export meets the absolute highest standards for:

Dimensional Tolerance: Ensuring tray edges and overall flatness are perfect for automated handling systems.

Perforation Consistency: Guaranteeing that every hole is uniform in diameter and burr-free, which is essential for hygiene and product release.

Structural Integrity: Designing the tray to withstand thermal stress without warping, providing a lifespan that far exceeds standard bakeware.

Tailored OEM/OED Services for the World

Hongbei excels in offering comprehensive OEM/OED services, making them a strategic partner rather than just a supplier. This involves working directly with clients to design bespoke solutions:

Customization for Global Ovens: Hongbei designs and manufactures Perforated Baking Trays to fit the exact dimensions and specifications of hundreds of different oven types used worldwide, accommodating everything from European convection ovens to American rack ovens.

R&D and Prototyping: For clients launching new products, Hongbei can quickly turn a concept into a prototype tray, leveraging their advanced tooling capabilities to test specialized perforation patterns and coatings, providing a crucial speed-to-market advantage.

Global Export and Partnership Focus

As a leading exporter, Hongbei’s business model revolves around reliable, high-volume production backed by rigorous quality control suitable for global logistics and regulatory environments. Their success is evidenced by their established supply lines to industrial bakeries and food equipment distributors across continents. They are the trusted source for companies that cannot afford product variation or equipment failure.

Contact Wuxi Hongbei Bakeware

To learn more about how Wuxi Hongbei Bakeware’s precision-engineered Perforated Baking Trays can optimize your production line, enhance product quality, and reduce operational costs, please contact us today.

Phone: +86 510 8283 1000 E-mail: [email protected]

Visit our official website for product details and services:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

/images/share.png)